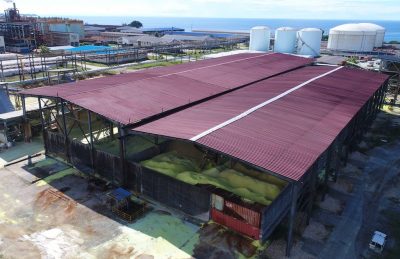

In Basamuk Refinery, a rain proof shed was constructed for the sulfur stockpile.

This is to reduce water content in sulfur, improve sulfur melting capacity and stabilize sulfuric acid production.

As the production capability of Basamuk Refinery increases and process become more stable, Acid Plant got more pressure on sulfuric acid production. The original open-air sulfur stockpile was plagued by rain, when it rains, the water content in sulfur increases suddenly, which poses great challenges for sulfur melting and increases the steam consumption and lowers the sulfur melting efficiency. Therefore, the company decided to construct this rain proof shed on the stockpile.

There were many high-risk works in construction like work at height, hot work and lifting work. With the comprehensive cooperation between the constructor MCC 19 and Basamuk Refinery, and the supervision of site HSE, there was no incident happened during the construction, which indicated the principle of safety first in Basamuk Refinery.

In January 2019, the rain proof shed was completed, and the effect was remarkable after it was put into use. The water content in sulfur was greatly reduced, daily sulfur melting capacity and efficiency was greatly improved.

The bottleneck of sulfur melting was broken through, which ensured the high-yield sulfuric acid production, and also provided a favorable condition for high-load and stable operation of the overall process of the refinery.

New Rain-Proof Shed for sulfur stockpile

Unloading of Sulphur at the wharf