Locals from the surrounding communities employed as Plant Operators at Ramu NiCo Management (MCC) Limited’s (RNML) Kurumbukari (KBK) Mine have recently undergone internal process plant trainings.

Through the Company’s corporate obligations for communities around the corridor of the Ramu Nickel and Cobalt Project to provide employment opportunities for locals, has seen more locals employed and trained in different departments in the mine at Kurumbukari and Basamuk Refinery since the mine began.

Last month, 60 operators who were employed locally from the surrounding communities to work in the Mine’s critical facilities; the Beneficiation Plant and the Wash Plant, have undergone the process plant operator training to up skill their knowledge as well as getting certificates on various vital components of the plant they operate in.

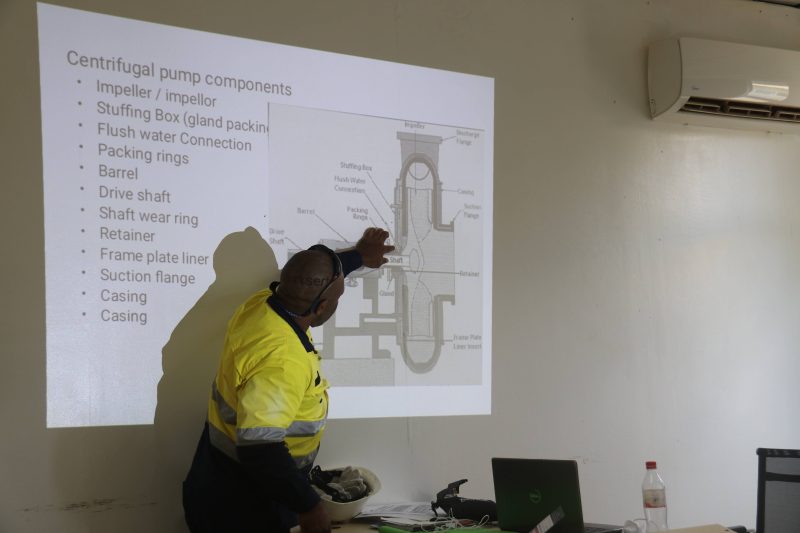

Trainer and Facilitator of the Process Training, Mr. Edward Yagama said most of the local operators needed to also know the different components of the machines they used every day and the training was purposely for that.

These local operators were introduced to the major equipment’s components and their operating principles.

“These local men were employed by the Company and worked for a long time and with such training that Ramu NiCo wants us to do, will make work easier for the locals employed, should they need to report defaults and also know which specific component of the plant needs trouble shooting,” Mr. Yagama, a mine process trainer by profession, said.

He said the first phase was theory and the second phase of the training was the practical component that involved trouble shooting and rundown of the different parts of the plant.

“It’s basically for them to know their equipment by heart and be more vigilant as they are the operators that everyday use and monitor the plants’ function,” Yagama added.

The trainer said that the operators are the custodian of the equipment they operate and for them to know the equipment they use is vital.

Mr. Yagama said the local operators have been working alongside other experienced operators for many years but lack the specifics of the plant and sometimes cannot identify the correct defaults for repair and have to wait for other experienced operators to identify the issue.

The trainer said, the upcoming training will be Basic Process Control and the type of controllers used at the Kurumbukari Mine’s processing facilities/plants.

Ramu NiCo’s KBK Mine Deputy Mine and Works Manager Mr. Mathew Francis said the mine has been providing employment opportunities to the impact communities for many years.

“These include assistant plant operators, truck and Volvo Operators as well as others that don’t require them to have specific skills training to apply,” the Deputy Mine Manager said.

He said with these internal trainings, it helps these employees to be certified and with their experience working in the plants and vehicle operator experience and can also be a useful resource for them to get promoted or more salary in RNML to improve their families’ living standards.

“Basically, what we are doing at Ramu NiCo is to localize the work force for the locals to be trained and work at the mine in the years to come instead of getting people from other provinces to come and work,” Francis added.

Jobs that require qualified personnel to take up are the ones that the Company recruits from outside.

Process Plant Training conducted by Mr. Yagama

Two operators from the Beneficiation Plant were taking the theory lesson